Apparatus 1 (Basket Apparatus)

The assembly consists of the following: a vessel, which may be covered, and made of glass or other inert, transparent mate-rial;1 a motor; a metallic drive shaft; and a cylindrical basket. The vessel is partially immersed in a suitable water bath of any convenient size or heated by a suitable device, such as a heating jacket. The water bath or heating device permits holding the temperature inside the vessel at 37 ± 0.5° during the test and keeps the bath fluid in constant, smooth motion. No part of the assembly, including the environment in which the assembly is placed, contributes significant motion, agitation, or vibration beyond that due to the smoothly rotating, stirring element. An apparatus that permits observation of the specimen and of the stirring element during the test is preferable. The vessel is cylindrical, with a hemispherical bottom and ♦with one of the following dimensions and capacities: for a nominal♦ capacity of 1 L, the height is 160–210 mm, and its inside diameter is 98–106 mm; ♦ for a nominal capacity of 2 L, the height is 280–300 mm, and its inside diameter is 98–106 mm; and for a nominal capacity of 4 L, the height is 280–300 mm, and its inside diameter is 145–155 mm♦ . Its sides are flanged at the top. A fitted cover may be used to retard evaporation.2 The shaft is positioned so that its axis is NMT 2 mm at any point from the vertical axis of the vessel and rotates smoothly and without significant wobble that could affect the results. A speed-regulating device

is used that allows the shaft rotation speed to be selected and maintained at the specified rate ♦given in the individual mono-graph♦ within ±4%.

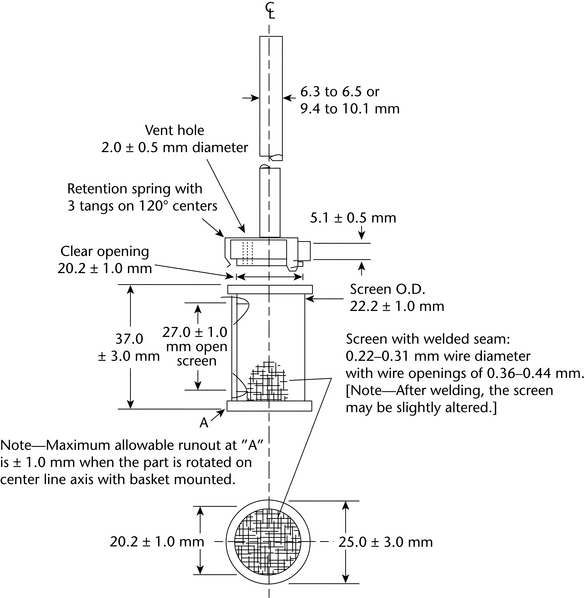

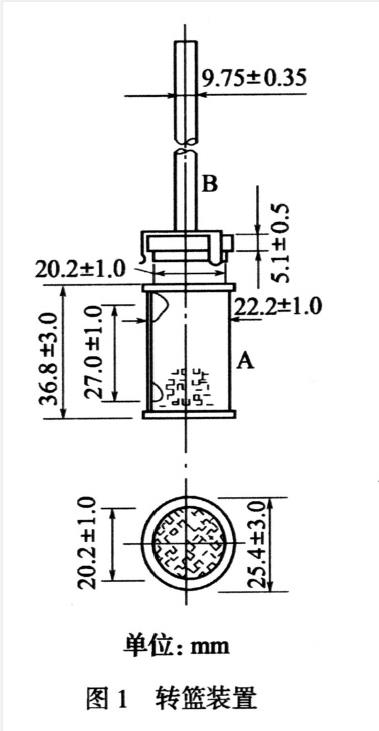

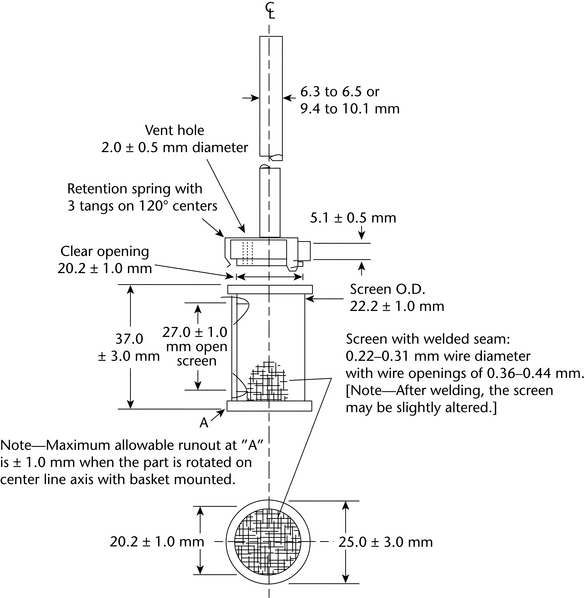

Shaft and basket components of the stirring element are fabricated of stainless steel, type 316, or other inert material, to the specifications shown in Figure 1. A basket having a gold coating of about 0.0001 inch (2.5 mm) thick may be used. A dosage unit is placed in a dry basket at the beginning of each test. The distance between the inside bottom of the vessel and the bottom of the basket is maintained at 25 ± 2 mm during the test.